Traceability case

business Task_

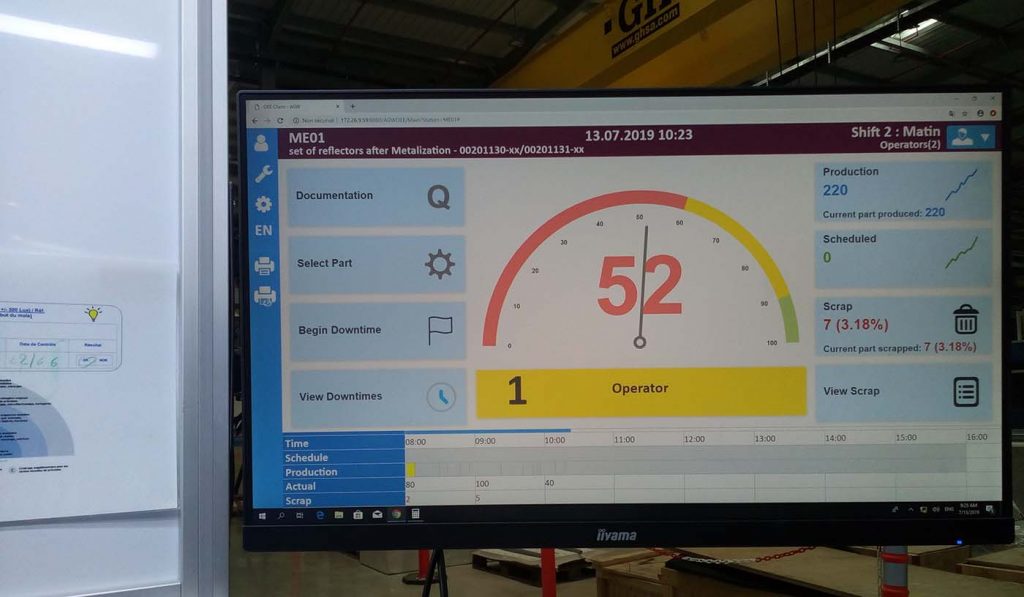

Traceability for automotive lighting production, productivity optimization for manufacturing processes.

Solution

We have been working with Varroc since 2012. In 2018,the client requested support in building a new plant. MES consultants visited on-site and adapted main OLSOM products to the new manufacturing requirements.

As a result, AGW Platform was integrated into the full workflow of business processes in the factory; AGW Visual integrated with new assembly lines to cover all main production processes.

Together with our partners we have launched an effective manufacturing that has grown into one of the biggest plants in the region in just a few years.

We started to work with the client from a green field and accompanied them while building the first assembly lines and launching all of the processes. Eventually, after three years, production has expanded to 13 lines.

During the process, we consulted specialists on the construction and organization of assembly lines.

After the integration, MES consultants held trainings for employees to help them learn the new software.

2018 – first three assembly lines launch with AGW IP (Platform) product

2020 – manufacturing grows to 13 assembly lines.

2021 – plant and software renovated and modernized

Process

Key challenges

The short timeline for product integration has been further reduced by the lack of electricity at the plant

All software had to be connected and adjusted in just two days