Manufacturing is at the forefront of rapid innovation, driven by technological advancements and global challenges. To stay competitive, businesses must adapt to changing landscapes with agility and foresight.

At this year’s Rockwell Automation Fair 2024, the theme “Make It Matter” highlighted the need for manufacturers to achieve measurable impacts through digital initiatives and a focus on sustainability.

Yuri Pilipenko, CEO of OLSOM, participated in the event and shared his perspective on how manufacturers are addressing today’s challenges and seizing new opportunities.

Key Industry Challenges

Manufacturers are navigating an increasingly complex landscape, balancing the demands of technological advancements, workforce changes, and global challenges. From meeting stricter regulatory requirements to ensuring cybersecurity and sustainability, these issues call for innovative solutions, smarter technology integration, and greater operational adaptability.

Among these challenges, two stand out as particularly critical to the future of manufacturing:

Supply Chain Resilience

Uncertainty continues to impact supply chains globally, with disruptions rising by 30% in the first half of 2024 compared to 2023. Key factors contributing to these challenges include:

- Extreme Weather Events: A 226% year-over-year increase in incidents, such as floods, hurricanes, and typhoons, severely impacted production schedules and inventory levels.

- Labor Issues: Strikes and labor disputes at critical points in the supply chain caused delays and rerouting, further complicating logistics.

- Cybersecurity Threats: Cyberattacks targeting supply chains added to the growing list of challenges, disrupting operations and compromising data integrity.

- Compliance Pressures: An increase in legal and compliance-related disruptions tied to ESG regulations.

Workforce Skills Gap

The manufacturing sector is grappling with a persistent skills shortage. As experienced workers retire, finding skilled workers to fill their roles has become increasingly difficult.

According to the 2024 Deloitte and the Manufacturing Institute Talent Study, the manufacturing sector will need around 3.8 million new employees between 2024 and 2033. Alarmingly, approximately 1.9 million of these positions could remain unfilled if manufacturers fail to address the skills and applicant gaps.

This shortage of skilled labor disrupts production schedules and strains supply chains, leading to delays and logistical challenges that hinder overall productivity.

Emerging Trends and Innovations

Despite these challenges, manufacturing continues to evolve with groundbreaking innovations that address pain points and unlock new potential.

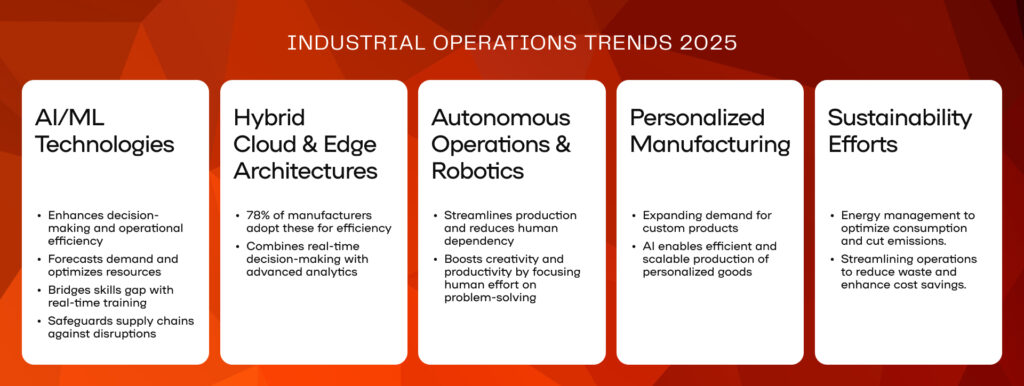

AI/ML Technologies

AI is transforming manufacturing by enabling smarter operations, enhanced decision-making, and streamlined processes.

- Demand Forecasting and Production Efficiency: AI helps manufacturers predict demand, optimize inventory, and reduce redundancies.

- Bridging the Skills Gap: AI-powered “copilot” tools offer real-time training to operators and maintenance staff, compensating for workforce shortages.

- Risk Mitigation and Cybersecurity: AI technologies safeguard supply chain integrity and drive proactive responses to potential disruptions.

AI is the key to modern manufacturing. It allows us to predict demand, plan capacities in advance, and prevent losses caused by unexpected machinery breakdowns or poor quality. By proactively preparing supply chains and making decisions based on past experiences, AI not only ensures the right materials are available at the right time but also plays a critical role in enabling autonomous operations and intelligent decision-making.

Yuri Pilipenko, CEO at OLSOM

Hybrid Cloud and Edge Architectures

Hybrid systems that combine edge and cloud technologies are setting a new standard for operational efficiency. 78% of manufacturers have adopted or are planning to adopt hybrid cloud and edge architectures to enhance their operations. This strategy not only improves data utilization but also ensures continuity during network disruptions, a critical factor in maintaining uninterrupted operations.

We need the best of both worlds. Edge systems handle real-time decisions and ensure operability, while the cloud provides advanced analytics and AI-driven insights.

Yuri Pilipenko, CEO at OLSOM

Autonomous Operations and Robotics

Automation and robotics are reshaping the shop floor. Manufacturers are prioritizing investments in robotics to address workforce challenges and enhance operational resilience. Autonomous robots are streamlining operations, improving consistency, and reducing the dependency on human intervention for repetitive tasks. These advancements free workers to focus on creative and problem-solving activities, enhancing overall productivity.

Personalized Manufacturing

The demand for customized products continues to grow, requiring manufacturers to rethink traditional processes. Yuri noted, “People increasingly want tailored products, which pushes manufacturers to adapt. This trend amplifies the need for robust supply chains and advanced planning tools.” AI and agile manufacturing processes are helping businesses deliver personalized goods efficiently and at a scale, turning what was once a niche offering into a standard practice.

Sustainability Efforts

Manufacturers are advancing sustainability efforts through two key approaches—direct and indirect:

- Direct Impact: Through the adoption of energy management systems, manufacturers can closely monitor energy consumption, identify inefficiencies in operations, and implement optimization processes to mitigate emissions.

- Indirect Impact: By streamlining production processes, minimizing material waste, and reducing rework, manufacturers can also lower their environmental impact. These practices lead to considerable cost savings.

If you’re looking to dive deeper into this subject, check out our recent article: Driving Sustainability in Manufacturing: How Smart Technologies Can Transform Your Operations

How OLSOM Supports Modern Manufacturing Trends

At OLSOM, we deliver practical, scalable solutions that empower manufacturers to overcome today’s challenges and achieve future growth. Our AGW Software offers a comprehensive set of functionalities designed to enhance efficiency, accuracy, and adaptability, perfectly aligning with the evolving demands of modern manufacturing:

- Enhanced Operational Efficiency: AGW streamlines production processes, tracks key performance indicators, and reduces human error, enabling smarter decision-making.

- Improved Quality and Compliance: With robust reporting and detailed traceability, AGW helps manufacturers minimize errors, meet regulatory requirements, and maintain high-quality standards.

- Optimized Inventory Management: AGW ensures accurate stock monitoring and efficient material flow, from initial receipt to final delivery, supporting smoother supply chain operations.

- Seamless System Integration: Acting as a centralized hub, AGW integrates and synchronizes data across manufacturing systems, creating a unified and efficient operational environment.

Conclusion

Modern manufacturing stands at a pivotal crossroads, faced with challenges ranging from supply chain inconsistencies to workforce shortages and sustainability pressures. At the same time, groundbreaking advancements like AI, hybrid cloud architectures, and autonomous robotics are reshaping the possibilities of what’s achievable. At OLSOM, we’re proud to contribute to this transformation, ensuring our solutions help manufacturers overcome challenges and embrace new opportunities.

Looking forward, manufacturing success will rely on seamlessly integrating cutting-edge technologies, human expertise, and sustainable practices—a vision OLSOM actively supports and advances.

Sources

- New Resilinc Data Reveals Supply Chain Disruptions Are Up 30% in the First Half of 2024

- Resilinc’s Special Report: Q2 2024 Review – Supply Chain Challenges and Potential Outlook

- 2024 Deloitte and the Manufacturing Institute Talent Study

- Understanding America’s Labor Shortage: The Most Impacted Industries

- 9th Annual State of Smart Manufacturing by Rockwell